function of load cell in universal testing machine|universal testing machine diagram : importing A load cell, crucial to force testing, is attached to the crosshead and is used to measure the material’s response to an applied force. Software is connected to the machine and used to control test method parameters .

O Ibis Styles São Paulo Barra Funda é um hotel temático onde a alegria e as cores da cultura latino-americana se misturam à decoração. Fique em quartos confortáveis com ar condicionado, Wi-Fi grátis, cofre, TV a cabo, secador de cabelo e frigobar. Além disso, o hotel é pet friendly e dispõe de quartos adaptados para pessoas com .

{plog:ftitle_list}

12 de fev. de 2024 · Correios - CDD Palmas, sem categoria. Rua NE 9, Lote 1 e 3, Quadra 104 Norte - Centro, Palmas - TO, 77001-032, Brasil, avaliação — 2.4/5. Localização no .

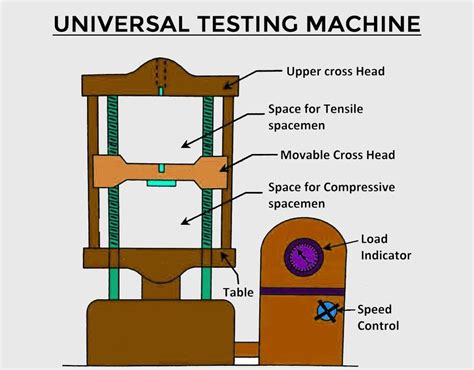

A universal testing machine consists of two main parts : Loading Unit; Control Unit; The arrangement of the test specimen and the exertion of the load is held in the loading unit. The variations in the application of the load and the corresponding test result are obtained from the .A Universal testing machine (UTM) is used to test the mechanical properties .

Depending on the arrangement of the strain gauges and the design of the load cell, a basic distinction is made between S- or Z-type load cells and ring or abbreviated R- type load cells.A Universal testing machine (UTM) is used to test the mechanical properties (tension, compression etc.) of a given test specimen by exerting tensile, compressive or transverse .The ATS Series 1100 Universal Testing Machine (UTM) is a versatile test frame capable of performing tension, compression, shear, and flexure tests. The Series 1101, Series 1105, and . A load cell, crucial to force testing, is attached to the crosshead and is used to measure the material’s response to an applied force. Software is connected to the machine and used to control test method parameters .

Load cell - A force transducer or other means of measuring the load is required. Periodic calibration is usually required by governing regulations or quality system. Cross head - A movable cross head (crosshead) is controlled to move up or .

Load cell. The load cell attaches to the cross head and provides a real-time reading of force in both tension and compression during the testing process. It should be calibrated per ASTM .

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break. A typical .General Description. The ATS 1600 Series Universal Test Machine (UTM) is designed to provide a versatile, fully integrated, modular testing system (figure 1). The system consists of a load .There are two main types of Universal Testing Machine , electromechanical and hydraulic, and the main components of UTM include the load cell, grips, crosshead, control panel, and software. Universal Testing Machine is widely .

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests .The TENSILON RTF is our newest universal testing machine offering innovative measuring possibilities, based on A&D's newly-developed and extensive technological knowledge. . A&D's world-class Class 0.5 testing .

Highly accurate load cells for MTS Insight and ReNew universal test systems are designed to offer world-class stiffness, stability, and linearity. They overload and side load protection, and are designed with built-in shunt resistors to facilitate regular verification of accuracy using calibration routines featured in MTS software.

Precision Universal Testing Machine Introductory Course (3) Test condition and results . AUTOGRAPH AGX-V2 3 Load Cell Universal Testing Machine. Material Testing; . AGX-V2, a stand-alone testing function using a large color LCD touch panel. Multifaceted Evaluation of High-Tensile Strength Joints b/w Dissimilar GA Steel & Al Sheet Materials. A universal testing machine diagram typically illustrates the load frame, crosshead, load cell, grips, and control system, highlighting the interaction of these components during a test. . Universal Testing Machine Function: Understand the universal testing machine function. Tags: Universal Testing Machine Price, .

A universal testing machine consists of two main parts : Loading Unit; Control Unit; The arrangement of the test specimen and the exertion of the load is held in the loading unit.The variations in the application of the load and the corresponding test result are obtained from the control unit.. In the figure-2, the left unit with table and crosshead form the loading unit.A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive strength. It is widely used for both small and large load testing in quality control or research projects, etc.

The ATS Series 1100 Universal Testing Machine (UTM) is a versatile test frame capable of performing tension, compression, shear, and flexure tests. The Series 1101, Series 1105, and Series 1110 are benchtop models with . The unit will not function without the load cell connected. 5. Connect the line cord to the line cord connector provided on .The LS universal materials testing machines are easy-to-use materials testing machines providing the highest level of performance for production testing. Find our materials testing machines here. . with an impressive ±0.5% reading accuracy down to 1/100th of the load cell capacity. This enables engineers to have the utmost confidence in .

universal testing machine snr

basic distinction is made between S- or Z-type load cells and ring or abbreviated R-type load cells. (S, Z- and R-type load cell). Depending on their design, the cells differ regarding overload and lateral force resistance. R type design S/Z type design Fig. 2: R type load cell Fig. 3: S/Z type load cell Fig. 1: Wheatstone's bridgeLoad Cell: High precision USA made Interface load cell offers high stiffness, high stability, and high linearity Over load protection, lateral loading protection Bi direction allows tension and compression test Self-recognition (TEDS) function Regular self-calibration Working temperature: 55℃-90℃ Controller: Force accuracy is most affected by the range and accuracy of the load cell. UTMs may be fitted with a wide range of load cell force capacities. For example, a 10 kN capacity machine may be used with a 500 N load cell for a wire crimp pull test, and then switched to a 10 kN load cell for tensile testing on a metal strip. 3. Encoder or Linear Scale Basic Introduction of UTM Machine: A Universal Testing Machine (UTM) is a type of mechanical testing equipment that is utilized for determining the mechanical properties of various materials, such as tensile strength, compressive strength, bending strength, and shear strength.The UTM works by applying a controlled tensile or compressive load to the specimen .

The zwickiLine table-top testing machine is equally ideal for research and development as for routine quality assurance testing. Development and manufacture of zwickiLine, including all mechanical, electronic and software .Tensile Testing Machine or Universal Testing Machine performs tensile, compression, flexion, shear tests, learn more. . In a tensile testing machine, load cells are used to measure the force exerted on the test specimen. . Load Indicator; Speed control; . The universal testing machine has two vertical threaded shafts. where the movable crosshead will slide on these vertical Bars. The Crosshead will be constant. These two heads will have .Explore Fine Manufacturing Industries for top-quality Universal Testing Machines (UTM) ensuring rigorous materials testing and superior quality assurance. +91 8087572455; . The specimen is subjected to load using a proper control valve. Functions of UTM. UTM is mostly used to assess the mechanical characteristics of materials. UTM regularly .

Our materials testing machines are used in R&D and for quality assurance in more than 20 industries. . Whether tensile test, compression test or flexure tests, function tests or standard tests, texture analysis or fatigue testing: with our product groups we offer testing solutions for test methods in R&D, as well as for quality assurance in .The NEXT GENERATION 6800 Series universal testing systems range in capacity from 500 N to 300 kN and provide exceptional performance with unparalleled accuracy and reliability. Offering up to 5 kHz data acquisition and 0.5% accuracy down to 1/1000th of load cell capacity, the 6800 Series offers ultimate flexibility for any testing need.Maximum security is maintained on 600kN/1000 kN capacity Universal Test Machine by limit switch on the lower grip as well as the safety check valves on the hydraulic system. Hydraulic power unit works silently. 0-40 mm flat and 8-32 mm round samples can be tested on 600 kN capacity frame and 0-40 mm flat and 8-40 mm round samples can be tested .

water vapor permeability test procedure factories

The 3400 Series Universal Testing Machines range in capacity from 500 N to 300 kN and are designed to meet all of your force testing needs. Instron’s patented Operator Protect system architecture makes the 3400 Series simpler, smarter, and safer than ever before. . The 3400 Series systems automatically stop when the load cell reaches .The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing. The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD). Which is calculated by determining the force required to deflect a test piece.Microdyno Tensile is the series of universal machines for tensile, compression, bending and peeling tests, developed for granting top-tier performances when testing all those materials requiring low loads (that is to say, up to 500 N).The unparalleled precision is granted by the 200.000 operative divisions of the load cells employed by Easydur, while the top versatility is .

Applied Test Systems (ATS) manufactures a wide range of standard and custom testing accessories to compliment our line of Universal Testing Machines (UTMs). Each grip and fixture is built using quality materials and designed to fit and function with the highest performance on all makes of ATS UTMs, as well as any existing models manufactured .The GCTS UTM‐500 is a servo‐hydraulic load frame with exceptional control and accuracy designed for precise testing. Four‐column vertical standing assembly and threaded columns for cross head adjustment. Servo control with closed‐loop feedback from any of the eight (8) input channels or real‐time calculated function. The UTM load frames can accommodate a large .NextGen offers cost-effective Universal Testing Machines to test multiple properties such as tensile, compression, flexure, tearing, bending and more. . It is defined as the change in rate of strain in a material as a function of stress. It can be referred to as the tensile modulus if measured relative to tensile testing. . A load cell is .

water vapor permeability testing equipment factories

Teste grátis. O FamiSafe é um poderoso aplicativo de controle parental disponível em dispositivos Android e iOS. Ele ajuda os pais a rastrear a localização de seus filhos, definir limites de tempo de tela, bloquear aplicativos, detectar conteúdos perturbadores, etc.

function of load cell in universal testing machine|universal testing machine diagram